Obviously, the harnessing of very low heads is only possible when there exists a hydraulic diversion infrastructure creating the potential head. However, even in this case, their profitability comes up against the following facts:

It is of primary importance to reach a profitable solution to optimize the costs of construction works. The following chart shows the exponential increase of the concrete volumes required for the construction of a hydroelectric power plant as the head decreases. It is based on statistical studies performed on many real cases and hydraulic calculations for the sizing of intake and draft tube.

For heads < 3m the impact of concrete volume (i.e. costs for civil works) soars incredibly!

Manca il Grafico

As an example, it can be seen that for an equal power, when coming down from a 3 m to a 1.5 m head, the concrete volume necessary to install a conventional solution is multiplied by 5.

The original design of the VLH turbo-generator unit enables overcoming this difficulty since it reduces civil engineering works to their minimum.

The following sections are comparing the existing technologies for very low head sites regarding the size and complexity of the Civil Work structures.

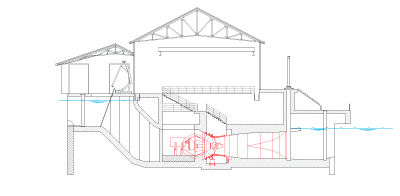

Axial turbine with upstream elbow

Axial turbine with upstream elbow

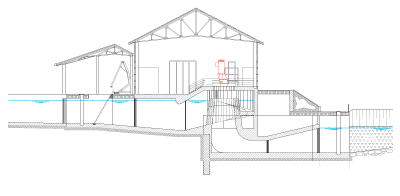

Vertical Kaplan

Vertical Kaplan

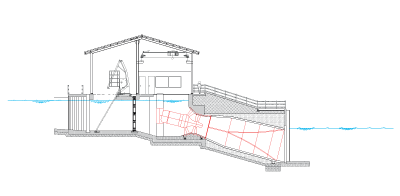

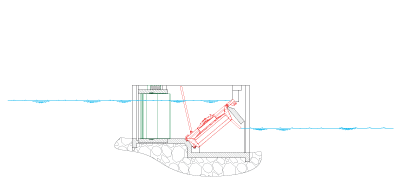

Ecobulbe inclined position with a building

Ecobulbe inclined position with a building

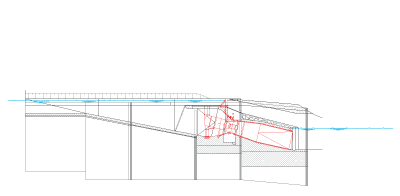

Ecobulbe inclined without building

Ecobulbe inclined without building

VLH

VLH

It is clear that the VLH offers a shorter lay out, with very simple shapes and less excavations.

The civil engineering infrastructures necessary for the installation of a VLH are thus reduced to their most basic expression, limiting themselves to two parallel vertical side-walls and an horizontal bottom platform. The excavation volumes are also optimized thanks to the unit inclination.