The equipment control is based on a Siemens industrial programmable logic controller. It performs the following functions:

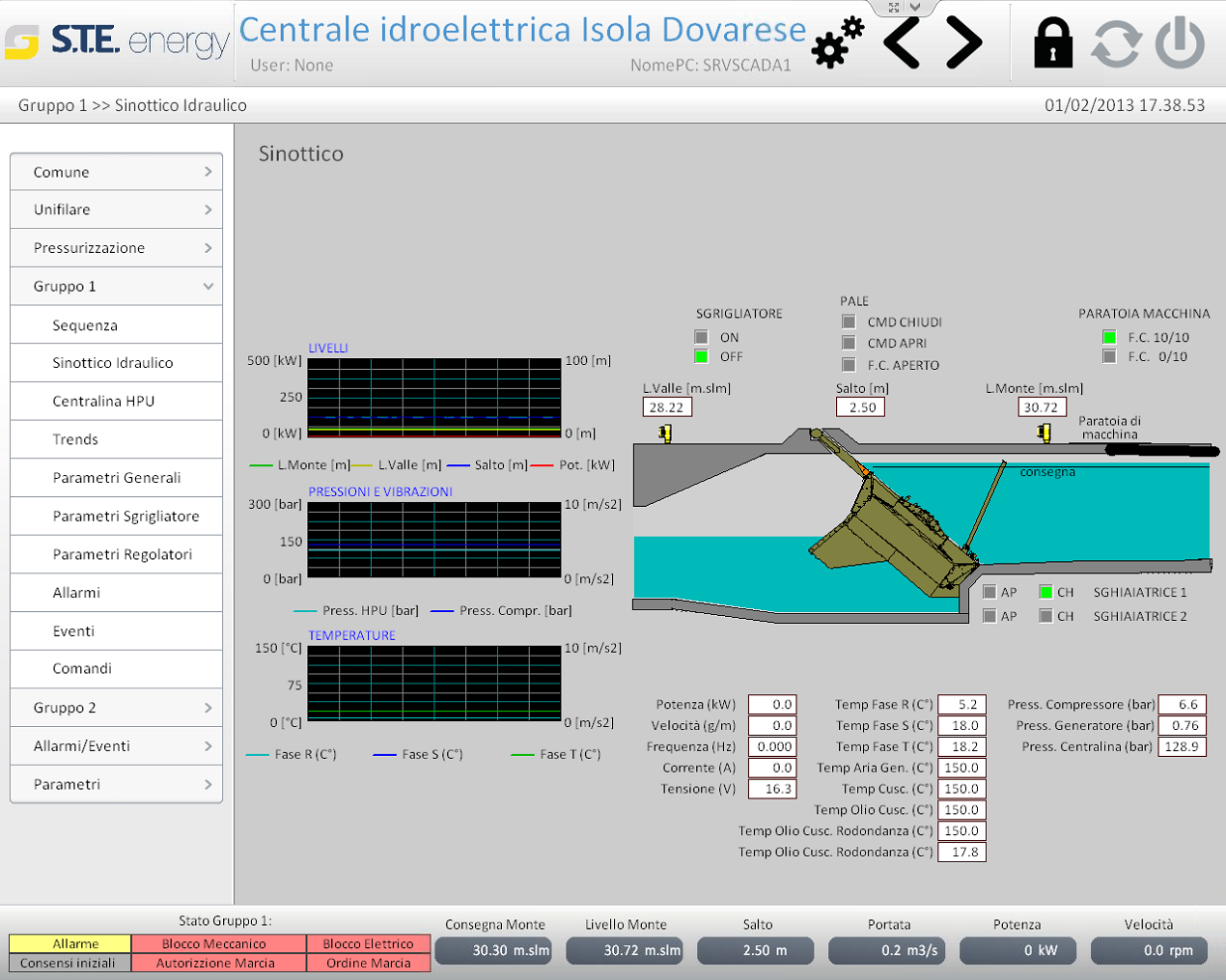

The central system controller defines the operating parameters of the turbine based on the head height measurements and other operating parameters, with the same principle as the logic controller used for conventional equipment.

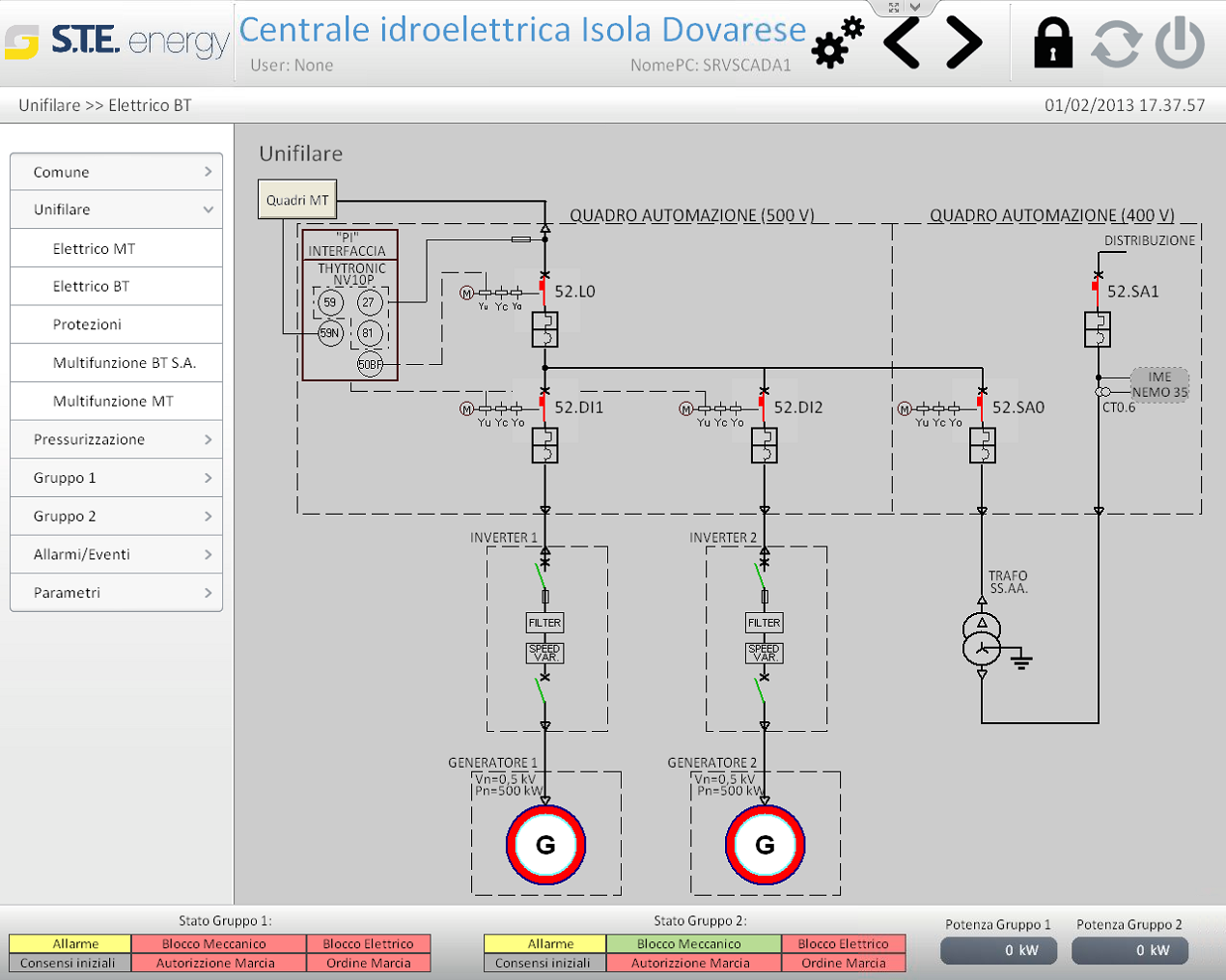

The power generated by the generator is rectified. This power transits through a D.C. bus, maintained at a stable value of approximately 800 Vcc, after which it is delivered to the electric network by the inverter. The entire power conversion chain is managed by the control unit. The system thus generates a high-quality three-phase electric power (few harmonics and little power fluctuation), with a power factor equal to one or adjustable on demand. The system synchronization, the coupling to the electric network and the decoupling from it are fully automated.

The user interface is accessible through a touch screen and is formed of a few screen pages. This interface enables to view the operating parameters, to perform manual control operations, and to change the operating parameters (approximately twenty).

A communication with the outside is possible via the modem. The user interface is remotely accessible by means of an Internet browser. The user interface is similar to that of the touch screen located at the front surface of the power cabinet.

The entire system can be remotely accessed. The access level is managed by a password and standard protections will be activated in the controller. It is also possible to configure the system for an automatic call back via the modem and for the automatic sending of urgent messages by modem or over the Internet. These options are to be specified during the project.

The system can be configured by means of tables of parameters stored in a database and available on the user interface. Only MJ2 can modify the operation logic of the system.

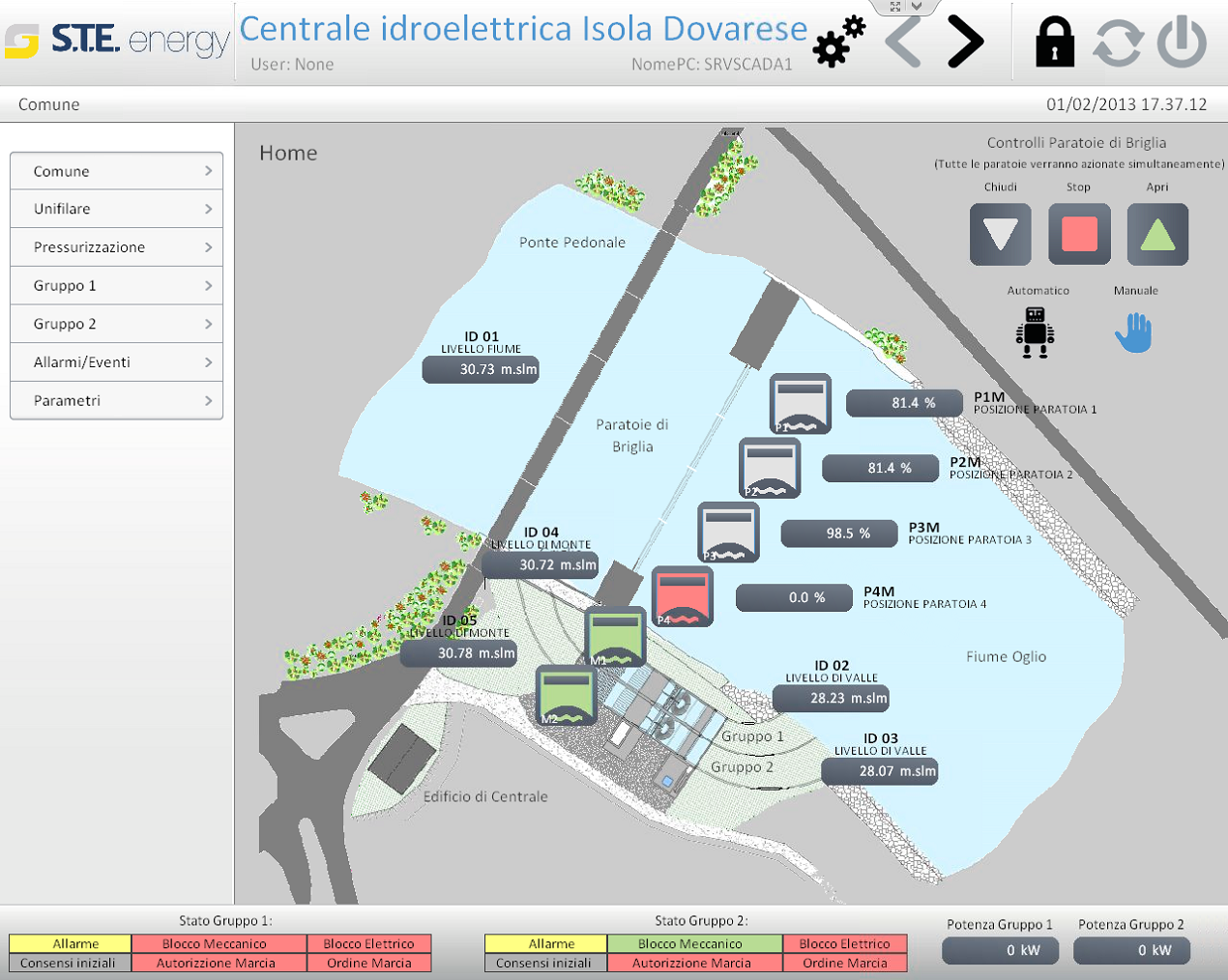

User interface screen of the Isola Dovarese Power Plant: