Hydraulic turbines are bulky by nature. Indeed, to generate even relatively moderate output (on the order of some hundred kW) under heads lower than 3 m, turbine flow rates can exceed 10 m3/s. This results, for water supply works, in large civil engineering structures proportioned to the collected flow rates.

To make their equipment more competitive, hydraulic turbine constructors have always endeavoured to optimize their product by increasing performances, in particular by a permanent research oriented towards the decrease of the runner diameters. This runner diameter decrease has led to water intake and outlet structures of a dimension such that their economical implementation is impossible when the head is too low.

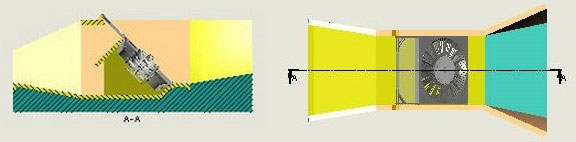

The basic idea of the VLH concept goes against this tendency by aiming at decreasing, as much as possible, intake and outlet structures by increasing the size of the turbine runner diameter and by integrating therein a self-supporting structure which ensures all the functions of a conventional facility.

The VLH incorporates the following functions: